Get To Know Your Car Better: A Detailed Guide To Automotive Terms — Engine Head

The term “engine head” typically refers to the cylinder head in an internal combustion engine. The cylinder head is a crucial component of the engine that sits on top of the engine block and covers the cylinders. It contains various components and performs important functions within the engine system. Take a trip down the technical lane to know everything about the engine head.

How Does The Engine Head Work?

The engine head sits above the engine block and contains the valves, which control the flow of air and fuel into cylinders and the release of exhaust gases from the cylinders. The camshaft opens and closes the valves at precise intervals, allowing the air-fuel mixture in and expelling burnt gases out. The head also has chambers where a part of the combustion of the air-fuel mixture occurs, which is responsible for generating power to move the vehicle. This makes the engine head an integral part of a vehicle with an internal combustion engine.

What Material Is Used To Make An Engine Head?

Engine heads are typically made from materials that can withstand high temperatures, pressures, and mechanical stresses while providing good thermal conductivity. Aluminum, Cast Iron, and Composite Materials are some of the most common materials used to manufacture engine heads.

Areas In An Engine Head

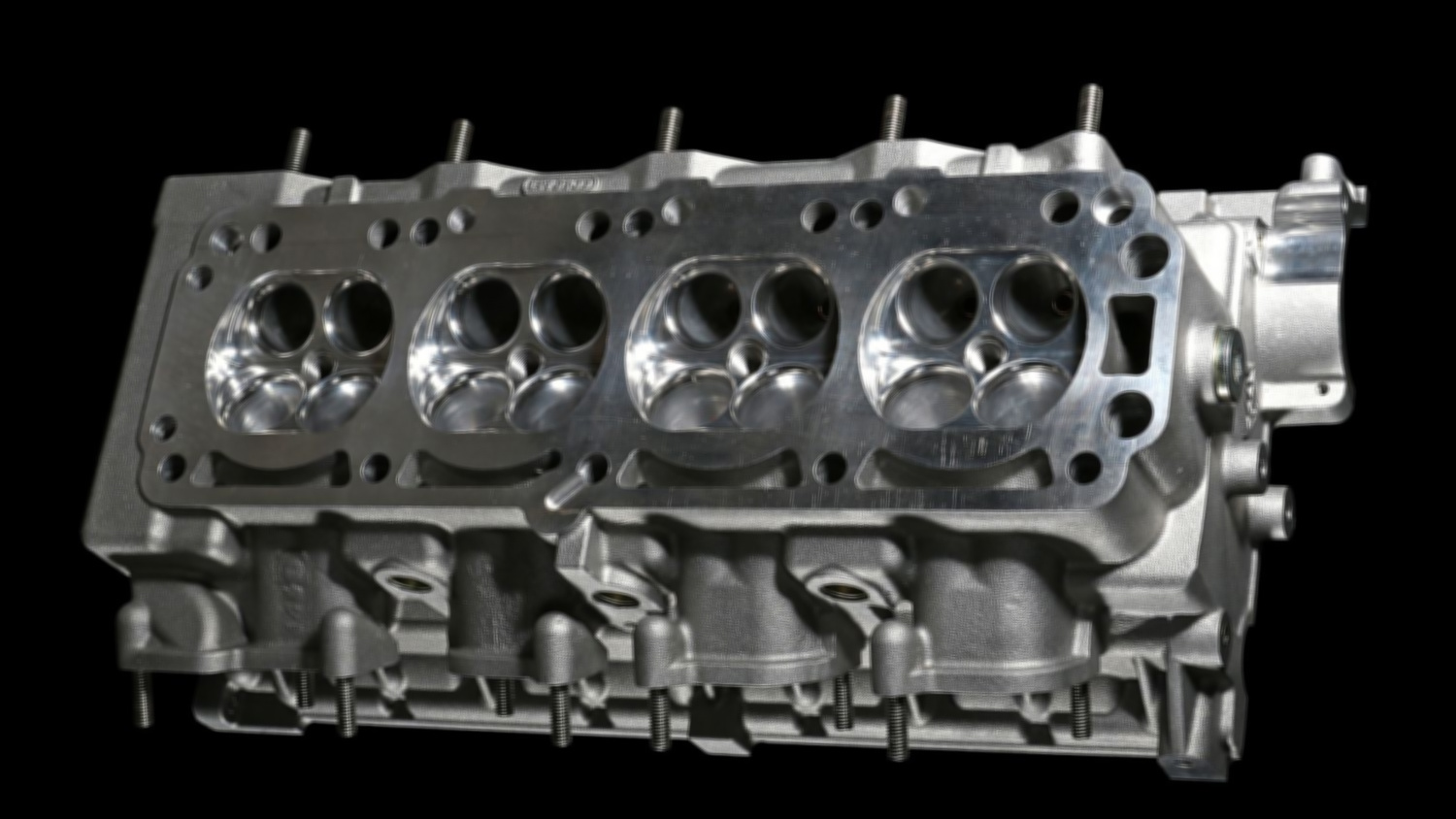

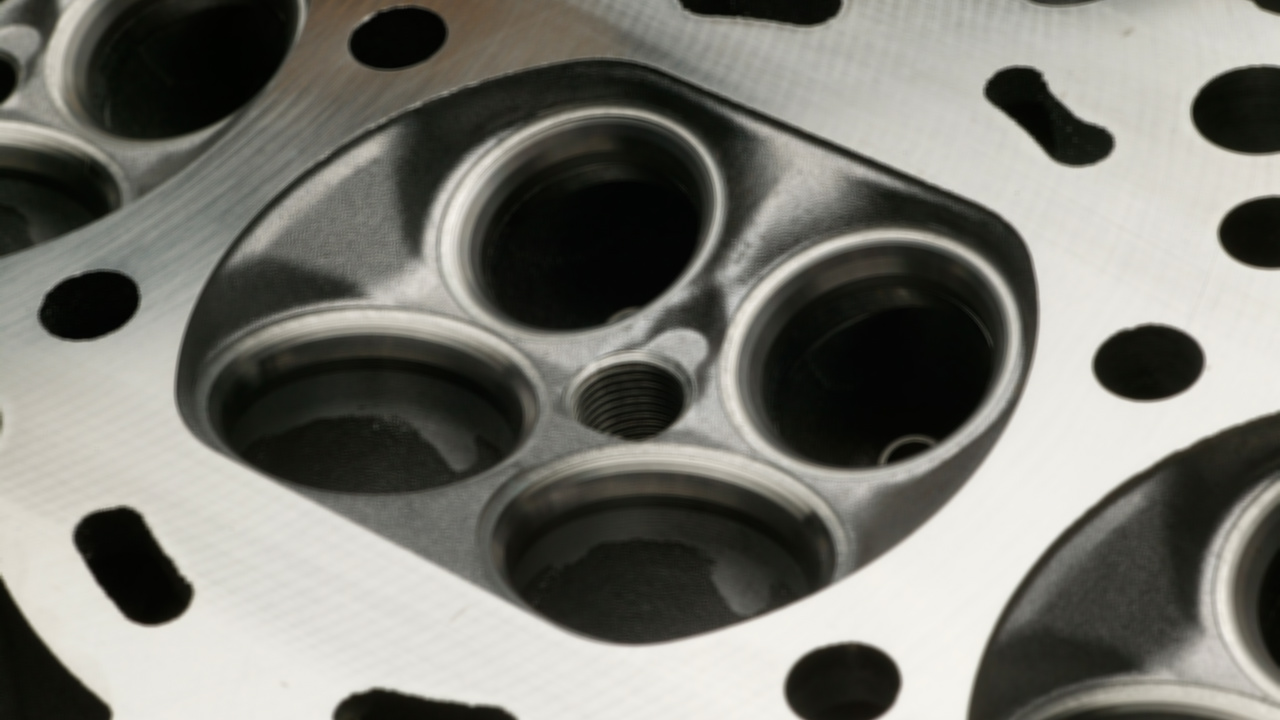

Combustion Chambers

The cylinder head houses the combustion chambers where the air-fuel mixture is ignited and burned, generating the power that drives the engine.

Valve Seats

Valve seats are machined surfaces in the cylinder head where the valves make contact when closed. They provide a tight seal to prevent combustion gases from escaping during the compression and combustion phases.

Intake and Exhaust Ports

These are passages that allow the intake of fresh air and fuel and the expulsion of exhaust gases. The design and shape of these ports significantly affect the engine’s performance characteristics.

Coolant Passages

Many engines have coolant passages in the cylinder head to help regulate the engine’s operating temperature. Coolant flows through these passages to absorb and dissipate excess heat.

Oil Passages

Cylinder heads also have oil passages that supply lubrication to various components, such as the camshaft and valve train.

Components In An Engine Head

Here are the main components and areas found in an engine cylinder head:

Valves

Cylinder heads contain intake and exhaust valves that control the flow of air and exhaust gases into and out of the combustion chambers. These valves are opened and closed by the camshaft, allowing fuel and air in and expelling exhaust gases after combustion.

Valve Springs

Valve springs are responsible for returning the valves to their closed position after they have been opened by the camshaft. They ensure proper sealing and functioning of the valves.

Valve Guides

Valve guides are cylindrical sleeves that guide the valves’ movement within the cylinder head, ensuring they stay aligned and move smoothly.

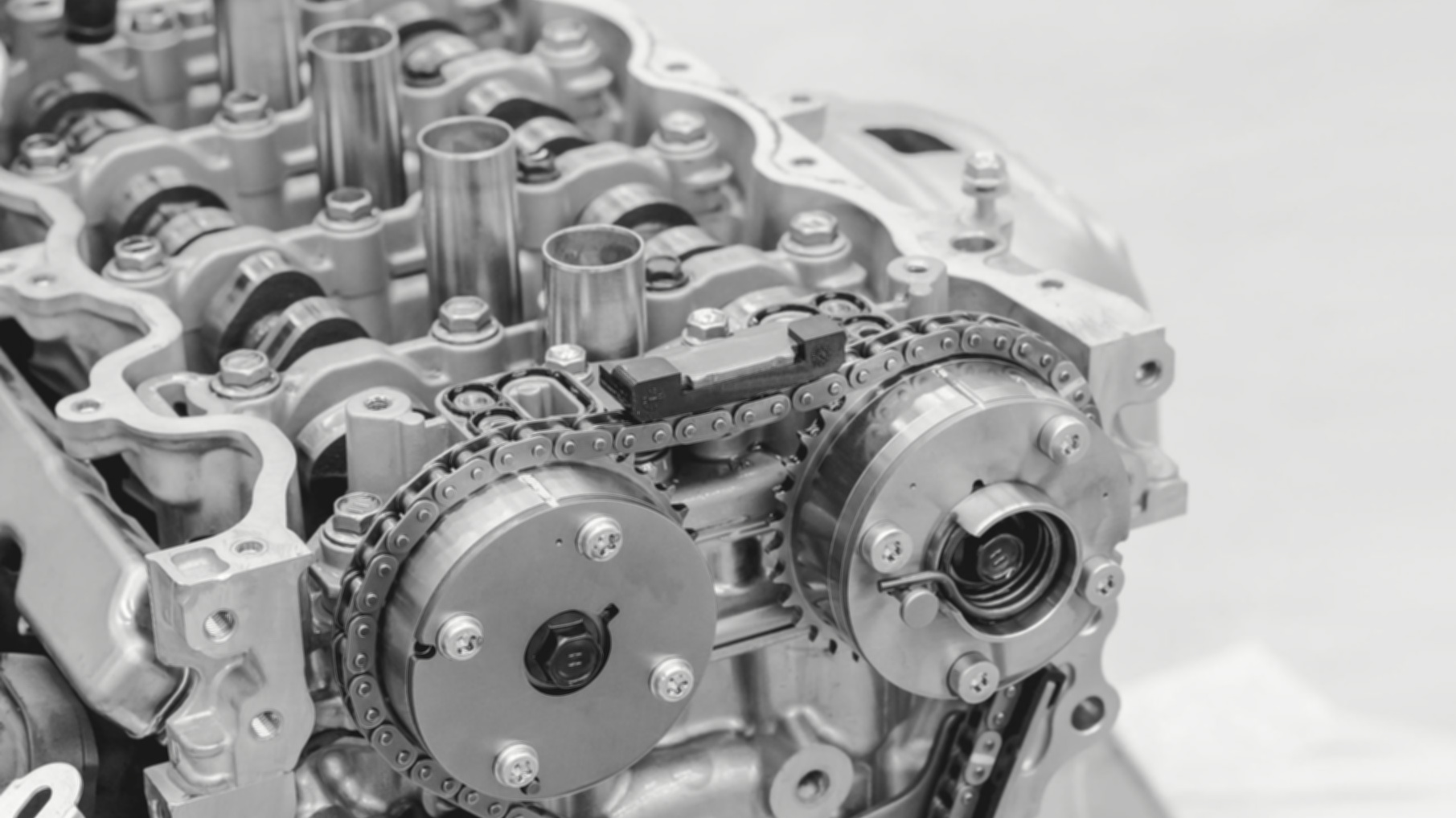

Camshaft

The camshaft is responsible for controlling the opening and closing of the valves. It is driven by the crankshaft and features lobes that push against the valve lifters, causing the valves to open and close at specific times.

Timing Chain & Timing Belt

Timing Chain and Timing Belt are both components used in internal combustion engines to synchronize the rotation of the crankshaft (which controls piston movement) and the camshaft (which controls valve movement). However, they have different materials, construction, and characteristics. Here’s a comparison:

- Timing Chain: It is typically made of metal, often steel, which makes them durable and capable of withstanding high loads and stresses. The timing chain is generally used in larger-capacity engines and is noisy due to metal-to-metal contact. Due to the metal construction, it lasts long, however, is costly to replace due to the excess labour involved. Timing chains are also generally placed inside the engine block.

- Timing Belt: Timing belts are usually made of rubber reinforced with fibres like fibreglass. They are quieter due to their flexible construction. Timing belts have a limited lifespan and need to be replaced periodically. Timing belt systems are generally less expensive than timing chain systems, however, it has to be replaced more often. Timing belts don’t require lubrication and are hence placed outside the engine block.

Spark Plugs

In engines with spark ignition, the spark plugs are located in the cylinder head. They ignite the air-fuel mixture within the combustion chamber.

Fuel Injectors

Fuel injectors will spray a mist of fuel to complete the air-fuel mixture required for combustion. The injectors are placed in the intake manifold or directly into the intake ports of the engine head. The specific location can vary depending on the engine’s design and fuel injection system.

- Port Fuel Injection (PFI): The fuel injectors are usually positioned in the intake ports of the engine head.

- Direct Fuel Injection (DI): Here the fuel injectors are placed directly inside the combustion chamber through holes or passages in the engine head.

Head Gaskets

Gaskets are used to seal the cylinder head to the engine block, preventing leakage of coolant, oil, and combustion gases.

Bolts and Fasteners

Bolts and fasteners secure the cylinder head to the engine block and ensure proper sealing and alignment.

Valve Technologies

The basic necessity of an engine is to have a minimum of two valves in its head: one for the inlet and another for the exhaust. As engine technology evolved, using multiple valves per cylinder was found to be beneficial. This enhances the efficiency and performance of the engine.

In layman’s terms, the faster the exhaust gases go out, the faster the fresh air-fuel mixture comes in, the faster the combustion. So a four-valve engine head performs better compared to a 2-valve setup. Generally, a four-valve setup can be found in cars while a 2-valve or a 3-valve setup can be found in smaller two-wheelers.

- Four Valves: 2 Intake Valves; 2 Exhaust Valves

- Three Valves: 2 Intake Valves; 1 Exhaust Valve

- Two Valves: 1 Intake Valve; 1 Exhaust Valve

Variable Valve Timing (VVT)

VVT is an engine technology that allows the timing of an engine’s intake, exhaust or both valves to be adjusted while the engine is running. This optimization of valve timing helps improve engine efficiency, power output, and emissions across a range of engine speeds and load conditions.

In a traditional fixed valve timing system, the valves open and close at a fixed time based on a predetermined camshaft profile. However, this timing might not be ideal for all operating conditions and engine speeds. VVT systems use various mechanisms, such as hydraulic actuators or electronically controlled solenoids, to alter the position of the camshaft in relation to the crankshaft.

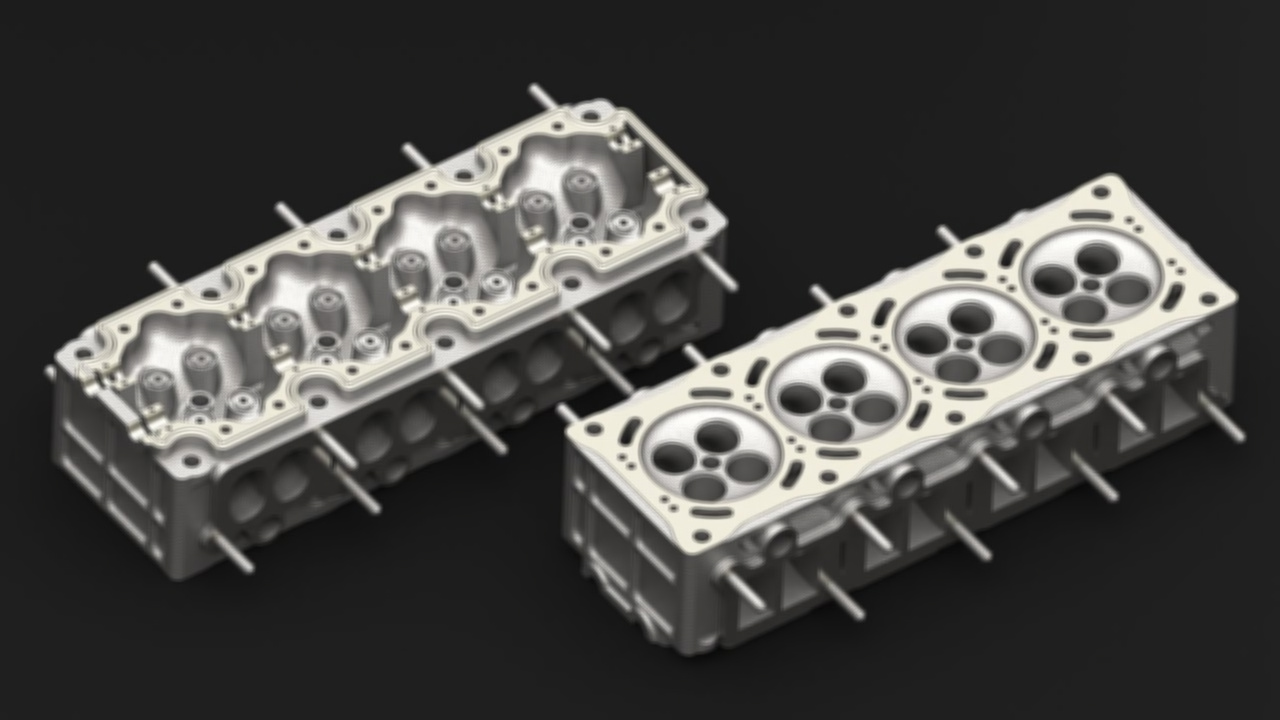

Types Of Engine Heads

Over the years, various configurations and valve placement designs in an internal combustion engine have resulted in various engine head designs and types. Here are some common engine valve configurations.

Overhead Valve (OHV) or Pushrod Configuration

Examples:

- 1999 Chevrolet Silverado 1500

- 2015 Dodge Charger R/T

In this configuration, the valves are located within the engine block, and pushrods and rocker arms are used to actuate them. This design is known for its simplicity but may have limitations in terms of high RPM performance.

Single Overhead Camshaft (SOHC) Configuration

Examples:

- 1999 Honda Civic Si

- 2012 Ford Focus SE

A single camshaft is positioned in the cylinder head to control both the intake and exhaust valves. It’s directly driven by the crankshaft through a timing belt or chain. This design offers better valve control than pushrod systems.

Dual Overhead Camshaft (DOHC) Configuration

Examples:

In a DOHC configuration, there are two separate camshafts, one for the intake valves and another for the exhaust valves. This allows for precise control of valve timing and higher engine RPMs. This particular configuration can implement the variable valve timing (VVT) technology for enhanced performance and efficiency.

Crossflow Configuration

Examples:

- 1990 Mazda MX-5 Miata

- 1992 Ford Escort RS Cosworth

In a crossflow configuration, the intake and exhaust ports are positioned on opposite sides of the cylinder head. This design promotes efficient airflow and better combustion characteristics.

Flathead Configuration

Examples:

- Ford Model T

- Willys Jeep

In flathead engines, both the intake and exhaust valves are located within the engine block, and they are often positioned in the engine block’s flat “head.” This design is simpler but can have efficiency limitations.

Radial Valve Configuration

Examples:

- 1984 Honda XR500RE

- 2023 MV Agusta Brutale 1000 RS

Radial valves are commonly used in motorcycle engines. The valves are positioned in a circular or radial pattern around the combustion chamber. This arrangement allows improved port size and shape, valve-included angle, and improved combustion chamber shape. It may also contribute to better cooling.

Rotary Valve Configuration

Examples:

- 1990 Norton Manx

- 2023 Ducati Panigale V4

Some engines use rotary valves that rotate to control the intake and exhaust flow. These valves can provide efficient and precise control but are less common. They are also generally found in motorcycles rather than cars.

There is your complete guide on the engine head of an internal combustion engine. We will be posting detailed blogs on other components of an internal combustion engine. Keep an eye on the DubiCars Blog section for more such guides. Here is a beginner’s guide to generic automotive terms.

Looking to own a car? Here is a list of used cars on sale in the UAE and new cars on sale in the UAE.