Get To Know Your Car Better: A Detailed Guide To Automotive Terms — Internal Combustion Engine

The combustion engine became an integral part of human evolution. If not for the combustion engine, we would still be at the mercy of “horse” power, quite literally. Travelling would still be an exploration activity. The invention of the combustion engine is one of the greatest blessings to mankind. Let’s learn a little about combustion engines in this article.

Before we learn about combustion engines, here is a beginner’s guide to general automotive terms that will help you to understand and speak about cars freely.

Internal Combustion Engine History:

The development of combustion engines traces back to the 17th century, with early hydrogen-fueled experiments. Thomas Newcomen’s atmospheric engine (1712) was a notable external combustion engine, used for pumping water from mines with coal-fired steam. In 1859, Etienne Lenoir crafted the first practical internal combustion engine using coal gas, employing a two-stroke design for stationary use.

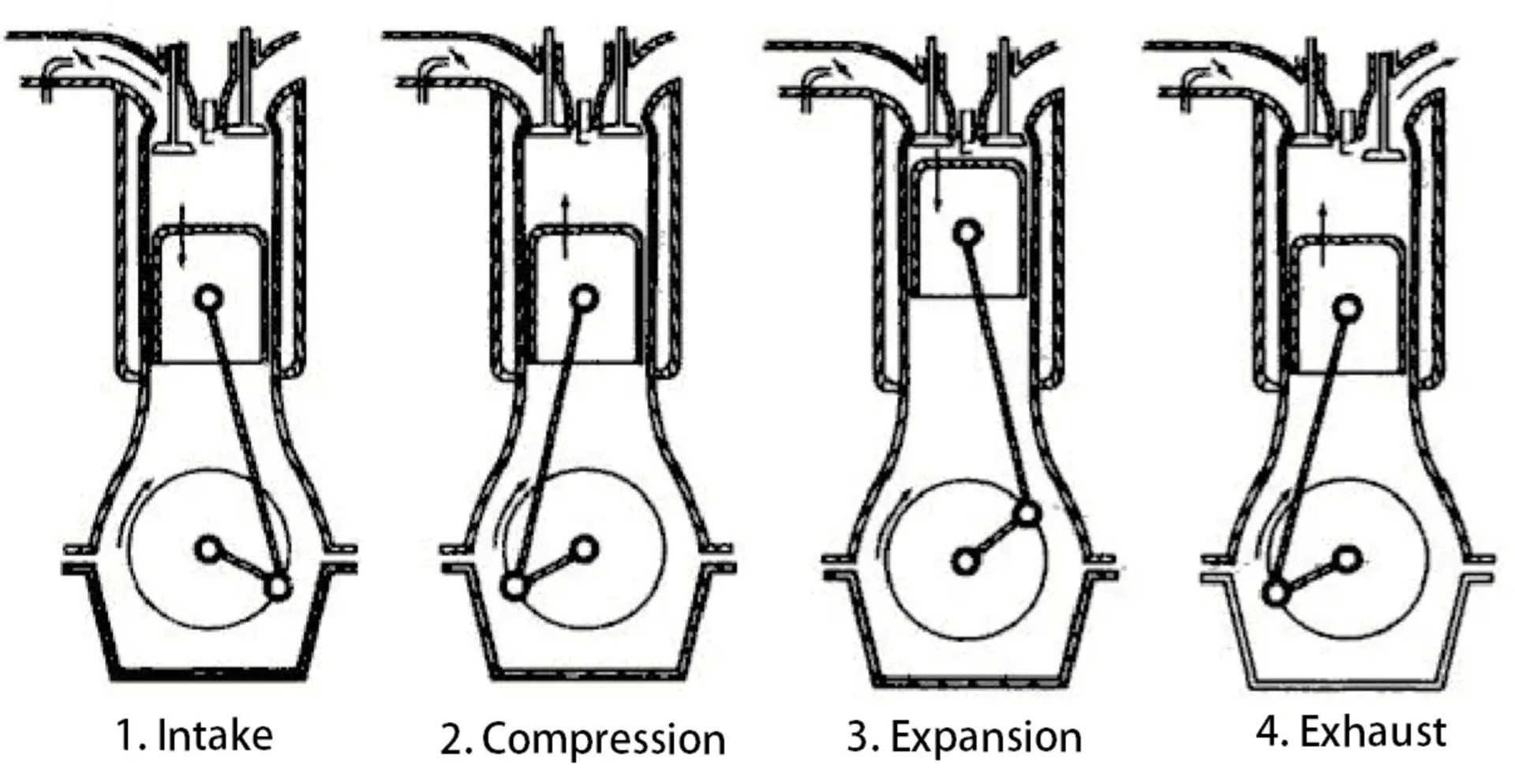

Nikolaus Otto’s four-stroke internal combustion engine (1876) featured the Otto Cycle: intake, compression, power, and exhaust strokes. Running on coal gas, it marked a pivotal advancement. In 1885, Gottlieb Daimler and Wilhelm Maybach created a gasoline-powered engine light enough for a bicycle, laying the foundation for future development.

What is an Internal Combustion Engine?

An Internal Combustion Engine (ICE) is a heat engine converting fuel’s chemical energy into mechanical energy through controlled combustion. Fuel and air ignite in a combustion chamber, creating expanding gases that move a piston connected to a crankshaft. This rotational motion drives wheels or machinery.

There are two primary types of internal combustion engines in terms of fuel:

Spark-Ignition Engines (Petrol Engines):

Example: Toyota Corolla

In these engines, a mixture of gasoline and air is sucked into the combustion chamber. The mixture is then compressed and at the same time, a spark plug creates a spark that ignites the mixture, causing combustion and the resulting expansion of gases drives the piston.

Compression-Ignition Engines (Diesel Engines):

Example: Isuzu D-Max

Diesel engines compress only air in the combustion chamber, raising its temperature. At a certain point in the compression stroke, fuel is injected into the highly compressed air, causing spontaneous ignition due to the high temperature. This combustion drives the piston.

Petrol Engine Vs Diesel Engine

- Petrol engines generally have a lower compression ratio compared to diesel engines.

- Diesel engines are generally more fuel-efficient than petrol engines. They extract more energy from the fuel due to the higher compression ratio.

- Diesel engines are known for their high torque output at low RPMs, which makes them ideal for heavy-duty applications.

- Petrol engines often produce higher power at higher RPMs, which can result in smoother acceleration and is generally found in light vehicles.

- Petrol engines are generally kinder to the environment with fewer emission gases.

- Petrol engines are generally quieter and smoother due to the spark ignition process.

Both petrol and diesel engines have their own advantages and disadvantages, and their suitability depends on the specific application and requirements of the vehicle.

Two-Stroke Engine Vs Four-Stroke Engine

Two-stroke and four-stroke engines are two distinct types of internal combustion engines in terms of their mechanism, operation, efficiency, and design. The primary difference between them lies in the number of strokes required to complete a full engine cycle, which includes intake, compression, power, and exhaust strokes.

Working Of A Two-Stroke Engine:

The two-stroke engine completes a full cycle in two strokes of the piston. The 2-stroke engine is simple in design and has a higher power-to-weight ratio. However, they are less fuel-efficient due to their faster cycle, and produce more exhaust emissions because the lubricating oil is mixed with the fuel.

- Intake/Compression Stroke: The piston moves upward, creating a partial vacuum in the cylinder. The intake port opens, allowing a mixture of air and fuel to enter the cylinder. As the piston reaches the top of its stroke, the intake port closes. The mixture is then compressed as the piston moves downward, closing the exhaust port as well.

- Power/Combustion Stroke: Near the bottom of the piston’s stroke, the spark plug fires, igniting the compressed mixture of air and fuel. The ignited mixture rapidly burns, creating a high-pressure gas that expands. This expansion drives the piston rapidly upward, creating power that is transferred to the crankshaft. At the same time, the exhaust port opens as the piston uncovers it.

Working Of A Four-Stroke Engine:

A four-stroke engine completes the combustion in four strokes of the piston. Four-stroke engines are generally more fuel-efficient and produce lower emissions compared to two-stroke engines. They are commonly used in most modern cars, trucks, motorcycles, and industrial applications.

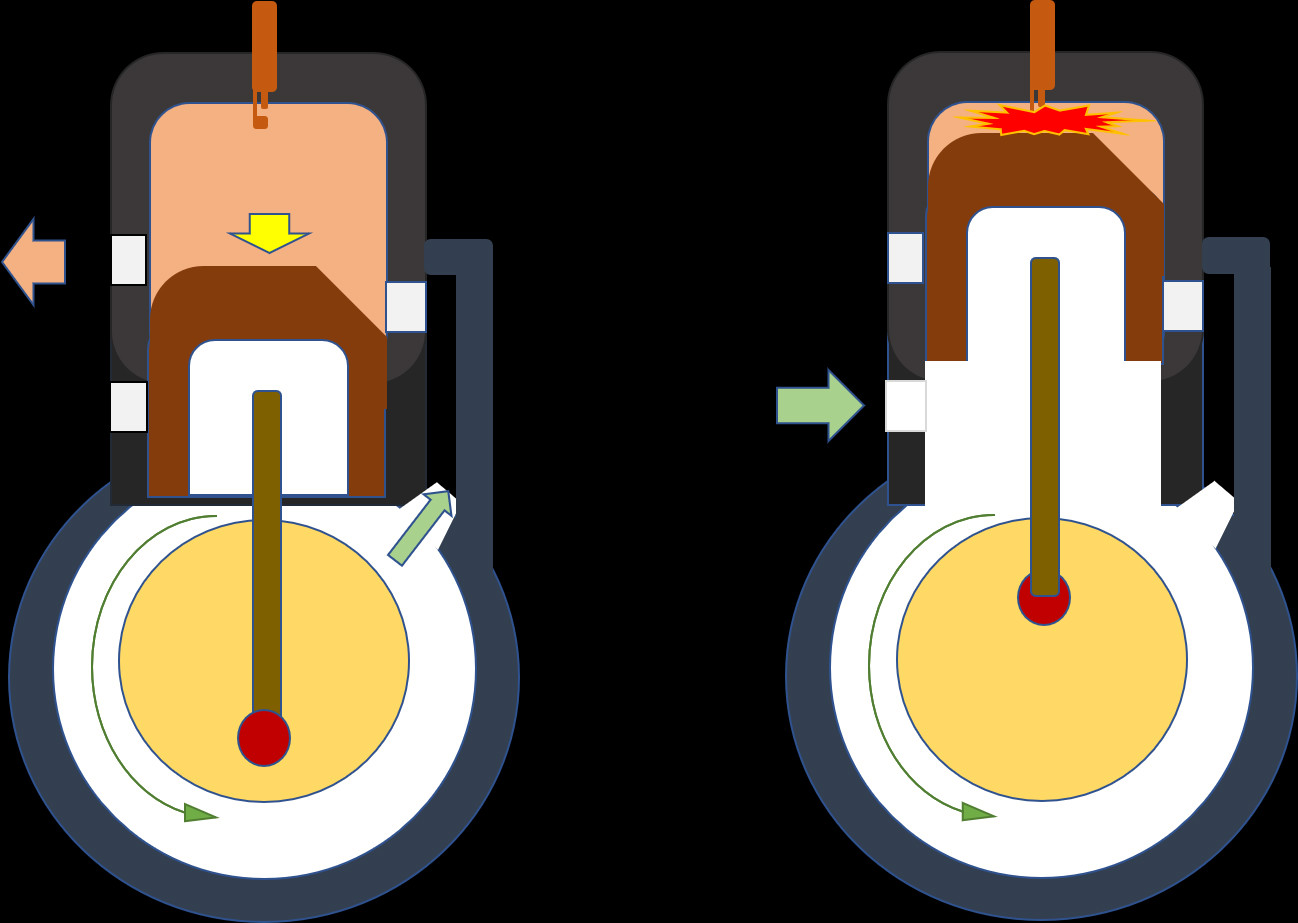

- Intake Stroke: The piston moves downward, drawing in a mixture of fuel and air through the open intake valve. The intake valve then closes.

- Compression Stroke: The piston moves upward, compressing the fuel-air mixture within the combustion chamber. This increases the temperature and pressure of the mixture.

- Power Stroke: At the top of the compression stroke, a spark plug ignites the compressed fuel-air mixture. The resulting combustion creates a rapid expansion of gases, forcing the piston downward. This is the power stroke, where the engine generates mechanical energy.

- Exhaust Stroke: After the power stroke, the exhaust valve opens, and the piston moves upward again. This pushes out the burned gases from the combustion chamber into the exhaust system.

Types Of Internal Combustion Engine

Spark-Ignition Engines (Gasoline Engines): These engines operate on the Otto cycle and use a spark plug to ignite a fuel-air mixture. They are commonly used in automobiles, motorcycles, and light-duty vehicles.

Compression-Ignition Engines (Diesel Engines): Diesel engines operate on the Diesel cycle and rely on the heat generated by compressing air to ignite the injected diesel fuel. They are widely used in trucks, buses, heavy machinery, and some passenger vehicles.

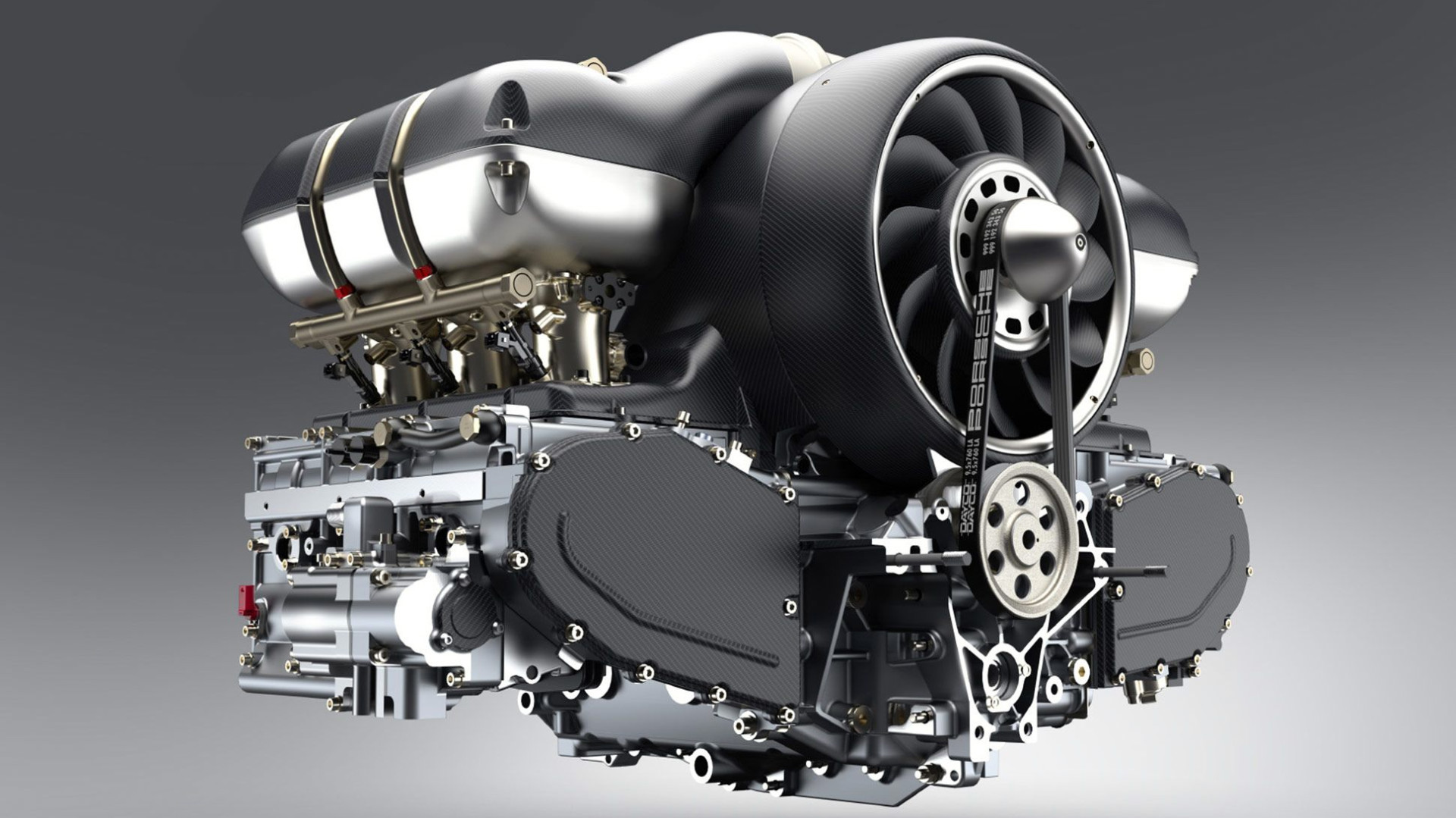

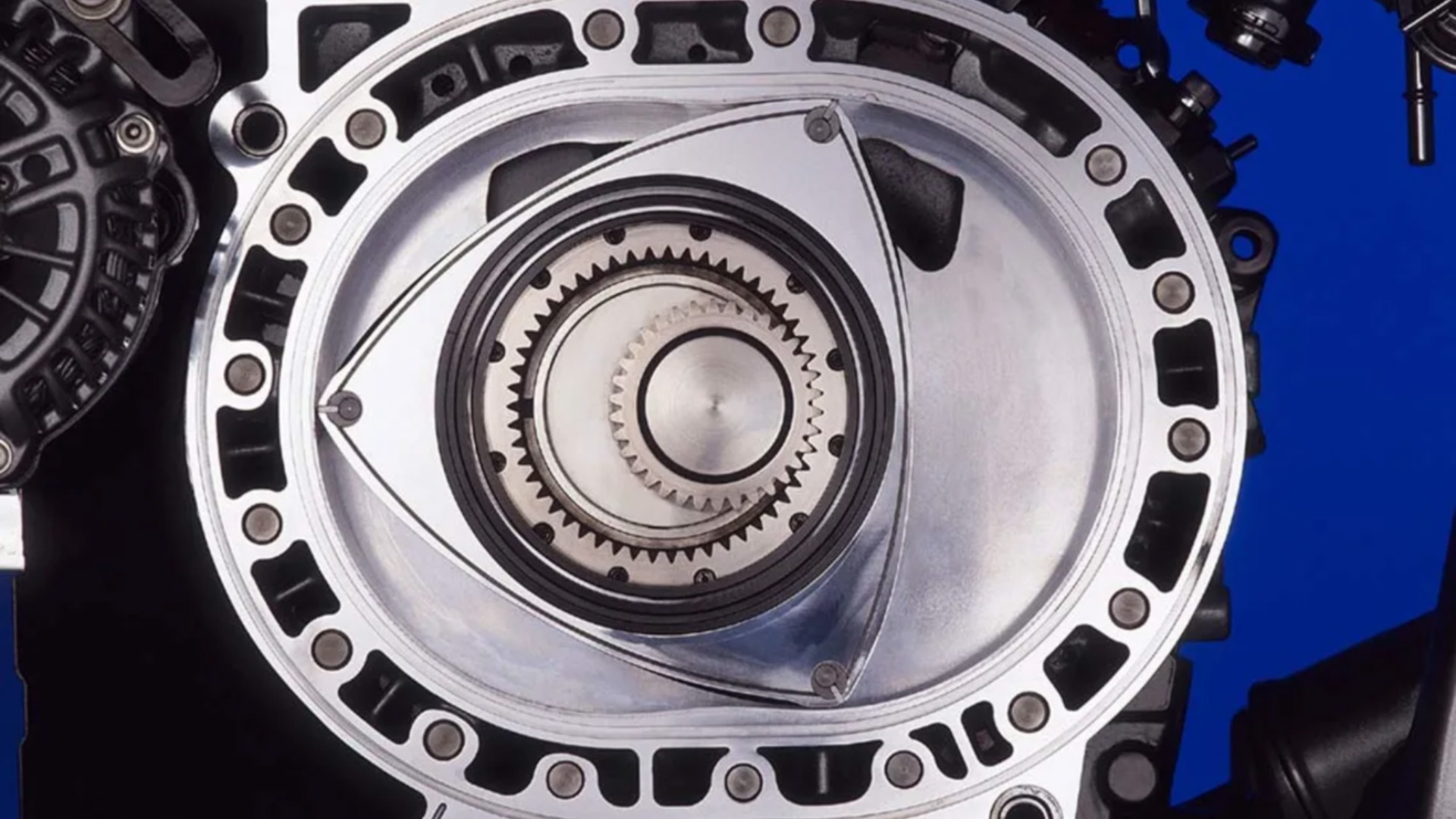

Wankel Engines: Also known as rotary engines, Wankel engines have a different design than traditional piston engines. They use a rotor instead of pistons to compress the air-fuel mixture and achieve combustion.

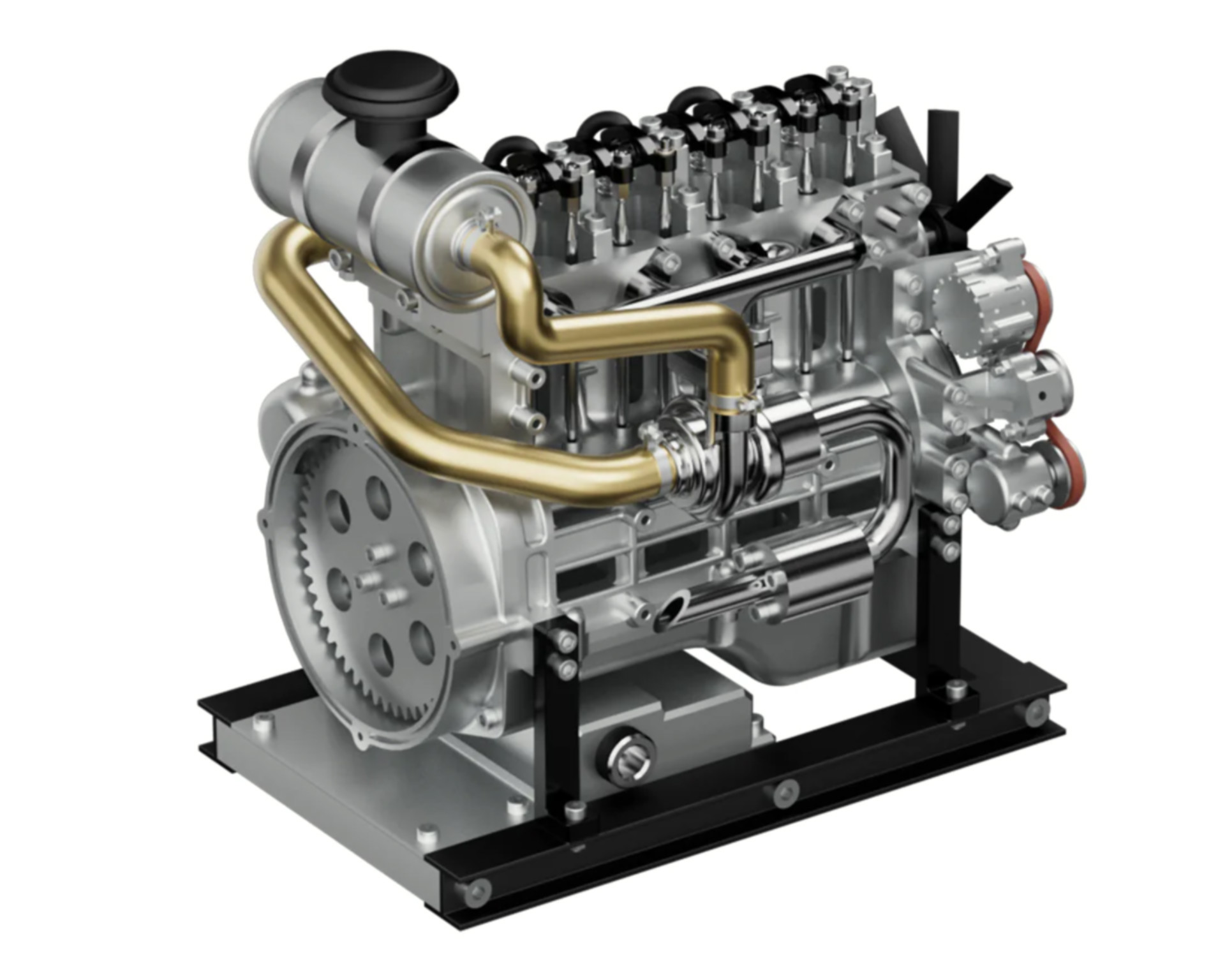

Naturally-Aspirated Engines: A naturally aspirated engine, often referred to as an “NA” engine, is an internal combustion engine that uses a vacuum effect to draw in air for combustion without the use of forced induction mechanisms such as turbochargers or superchargers.

Forced Induction Engines: A forced induction engine is a type of internal combustion engine in which the intake air is compressed to a higher pressure before entering the combustion chamber. This process results in an increased air density, which allows more oxygen to be present for combustion. This, in turn, leads to higher power output and efficiency compared to naturally aspirated engines.

Natural Gas Engines: These engines use natural gas as fuel, which can be either compressed natural gas (CNG) or liquefied natural gas (LNG). They are often used in industrial applications and some vehicles.

Hybrid Engines: Hybrid powertrains are a combination of an internal combustion engine with an electric motor and a battery pack. Hybrids are designed to improve fuel efficiency, reduce emissions, and enhance overall performance.

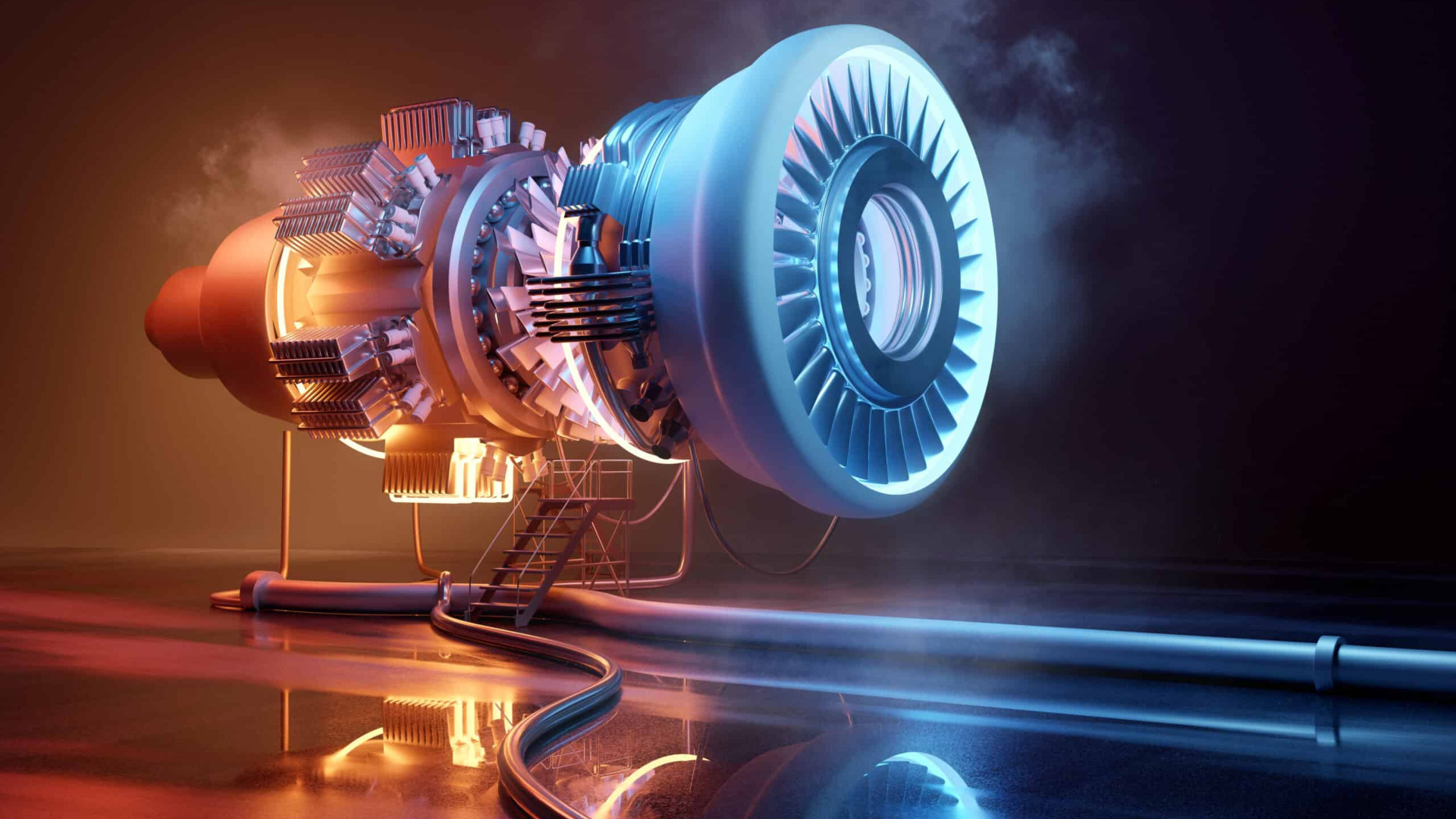

Jet Engines: Jet engines, such as turbojet and turbofan engines, are used in aircraft. They work on the principle of sucking in air, compressing it, mixing it with fuel, and igniting the mixture to create a high-speed exhaust jet that generates thrust.

Types Of Forced Induction Engines

Forced induction can be achieved through two primary methods: supercharging and turbocharging.

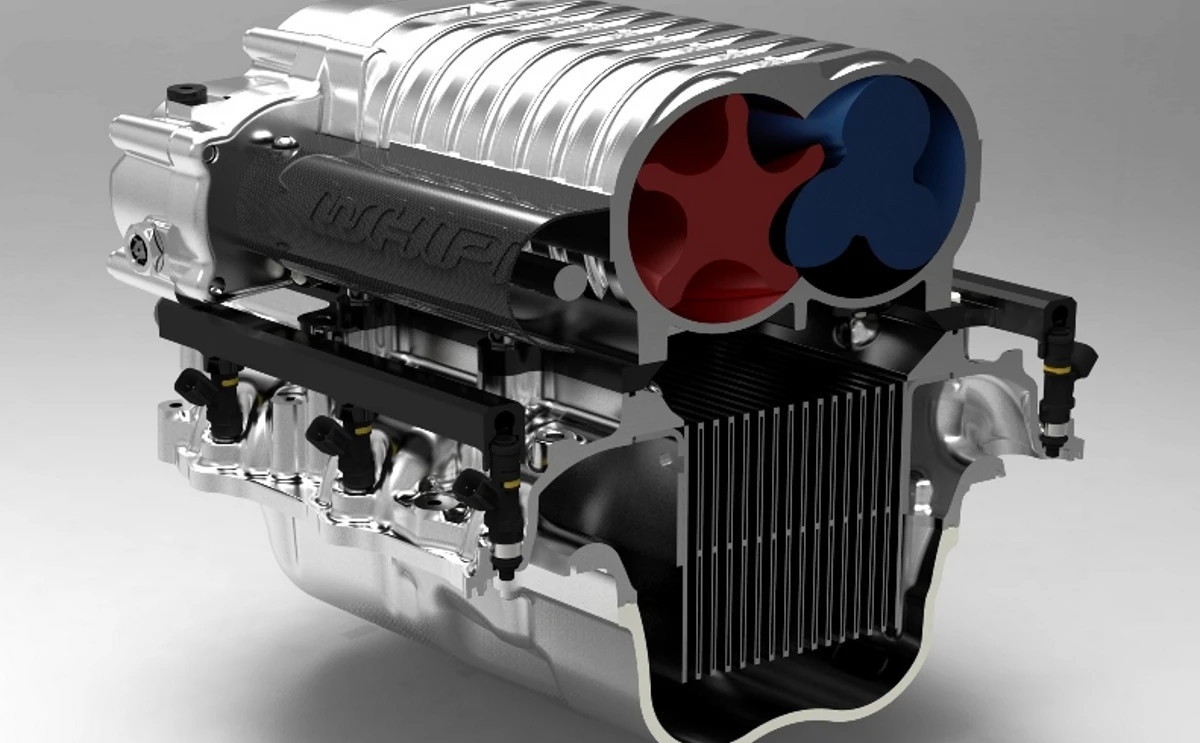

Supercharging:

Example: Chevrolet Camaro ZL1

In a supercharged engine, a mechanical compressor, known as a supercharger, is connected to the engine’s crankshaft. As the engine runs, the supercharger is driven by the engine’s rotation and compresses the incoming air before it enters the combustion chamber. This process increases the amount of air and fuel mixture that can be burned, resulting in improved power output.

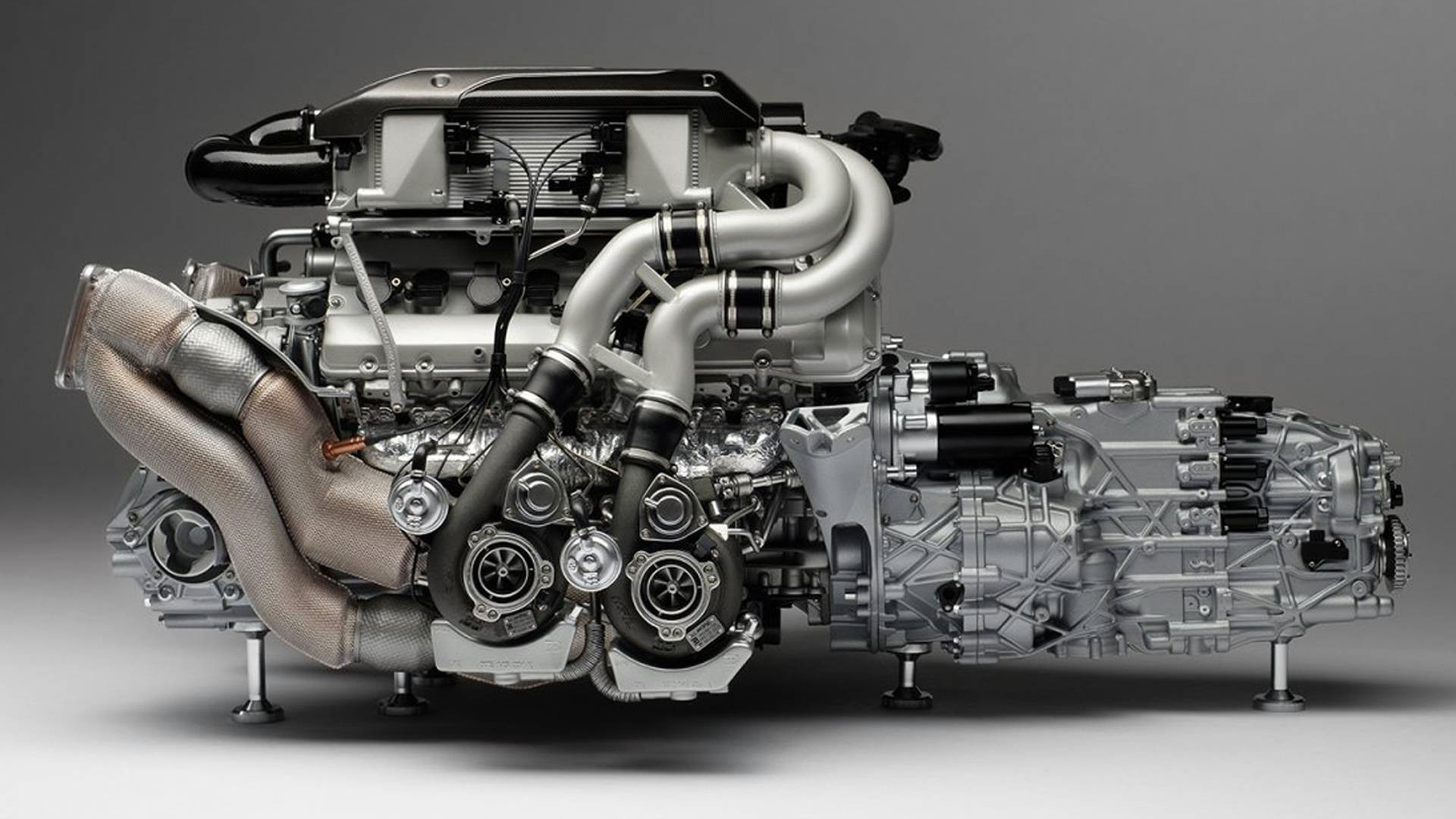

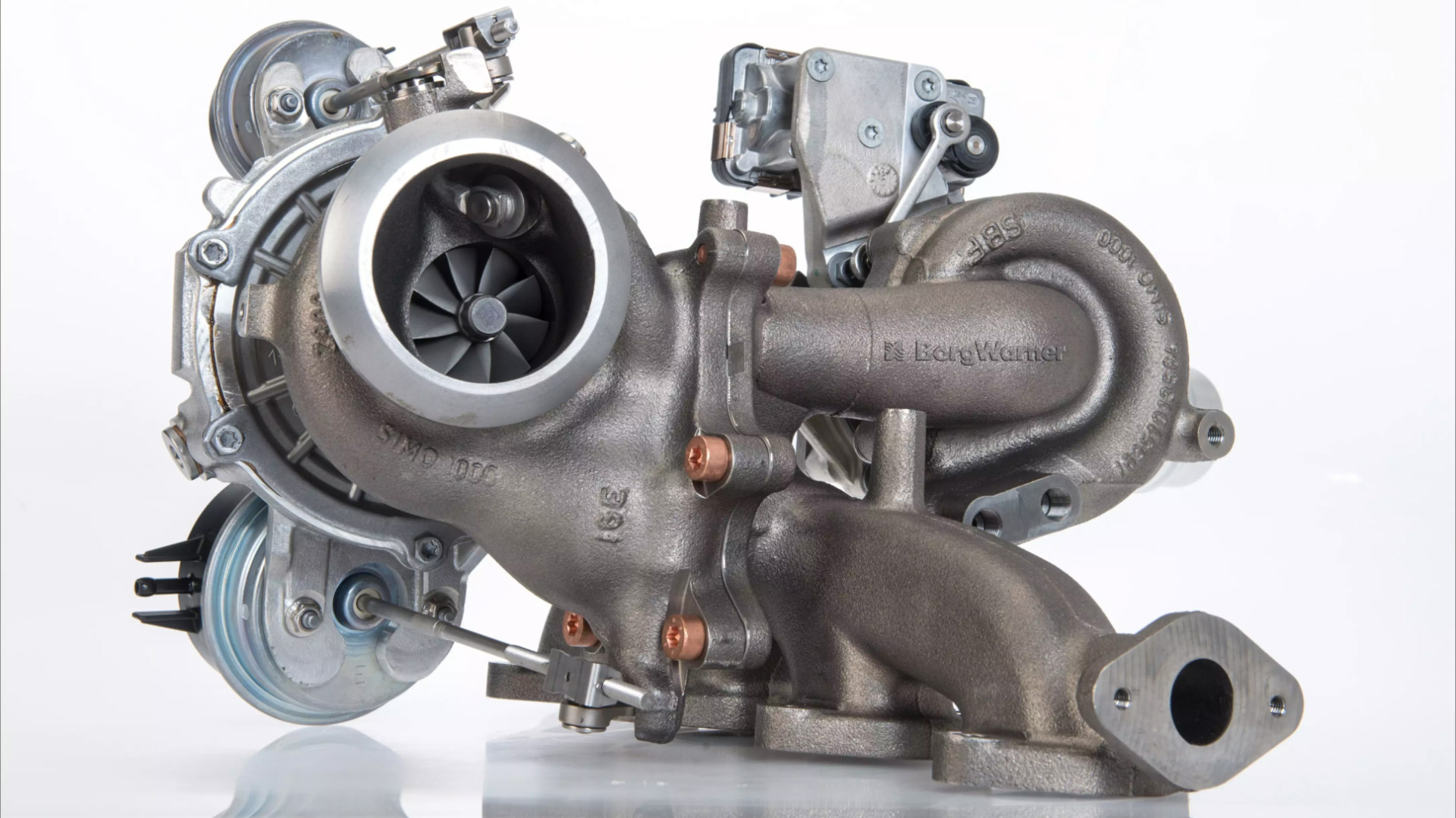

Turbocharging:

Example: Audi RS6 Avant

Turbocharging, on the other hand, uses a turbine-driven compressor called a turbocharger. The turbine is powered by the engine’s exhaust gases, which drive the compressor to compress the intake air. One key advantage of turbocharging is that it utilizes otherwise wasted energy from the exhaust gases to improve engine efficiency and power. Turbochargers are also known for causing “turbo lag,” a slight delay in power delivery due to the time it takes for the exhaust gases to build up enough pressure to spin the turbine effectively.

Forced induction engines are commonly used in high-performance and racing vehicles because they allow smaller engines to produce more power without increasing their physical size. However, due to stricter emission norms, automakers are now using forced induction engines along with hybrid technology to draw out more power from a smaller capacity engine, which will help keep the emissions in check. One such example is the Ferrari 296 GTB, on sale at DubiCars.

This is all you need to know about internal combustion engines and their working in particular. As mentioned earlier, if not for internal combustion engines, we would still be relying on animals to move about. The IC engine is slowly becoming a thing of the past as automakers are now looking at sustainable mobility options such as electric, hybrid, hydrogen and more.

Stay tuned to DubiCars for more detailed automotive guides released every week.

Looking to buy a car? Here are used cars for sale in the UAE and new cars for sale in the UAE.

Quality content is the important to invite the viewers to pay a quick

visit the web site, that’s what this web page is providing.

Great goods from you, man. I’ve understand your stuff previous to and you are

just extremely great. I actually like what you’ve acquired here,

really like what you’re stating and the way in which you say it.

You make it entertaining and you still take care of to keep it sensible.

I can’t wait to read far more from you. This is actually a wonderful website.