After figuring out a way to generate power using various sources, we needed an efficient way to use the power generated. This led to the invention of the gearbox, which helps in the transmission of power. A gearbox, also known as transmission, is a mechanical device used to adjust the speed and power output of a power source like an engine or motor.

Before we delve deep into the gearbox, read all about the internal combustion engine in this linked article. Let us get back to the gearbox and start with why a gearbox is needed.

Why Is A Gearbox Needed?

Reasons for using gearboxes include:

- Speed Adjustment: Gearboxes change rotation speed between input and output shafts. This is crucial when the source’s speed doesn’t match the required output.

- Torque Control: Gears in gearboxes can boost or lower torque (rotational force), adapting power to different tasks without straining the source.

- Load Adaptation: Gearboxes let machinery cope with varying torque and speed demands without altering the power source itself.

- Direction Change: Gearboxes can reverse rotation direction, helpful in cases like wind turbines.

- Efficiency: Gearboxes can optimise efficiency by picking gear ratios that minimise energy loss.

- Power Sharing: Gearboxes divide power from one source to different components or systems, each with distinct speed or torque needs.

- Control & Flexibility: Gearboxes provide extra control over machinery, adjusting speed and torque for different jobs.

Placement Of Gearbox

- Front-Engine, Rear-Wheel Drive: Gearbox at the rear, connected to the rear axle for balance.

- Front-Engine, Front-Wheel Drive: Transverse gearbox integrated with the engine in front for space efficiency.

- Front-Engine, All-Wheel Drive (AWD): AWD can have a front, rear, or centre gearbox based on layout.

- Mid-Engine: Gearbox behind the engine, balanced weight distribution for sports cars.

- Rear-Engine: Rear gearbox for unique weight distribution and traction.

Four-Wheel Drive (4WD): Transfer case houses gearbox for 4WD modes. - Electric & Hybrid Vehicles: Single-speed gearbox for electric motor to wheels.

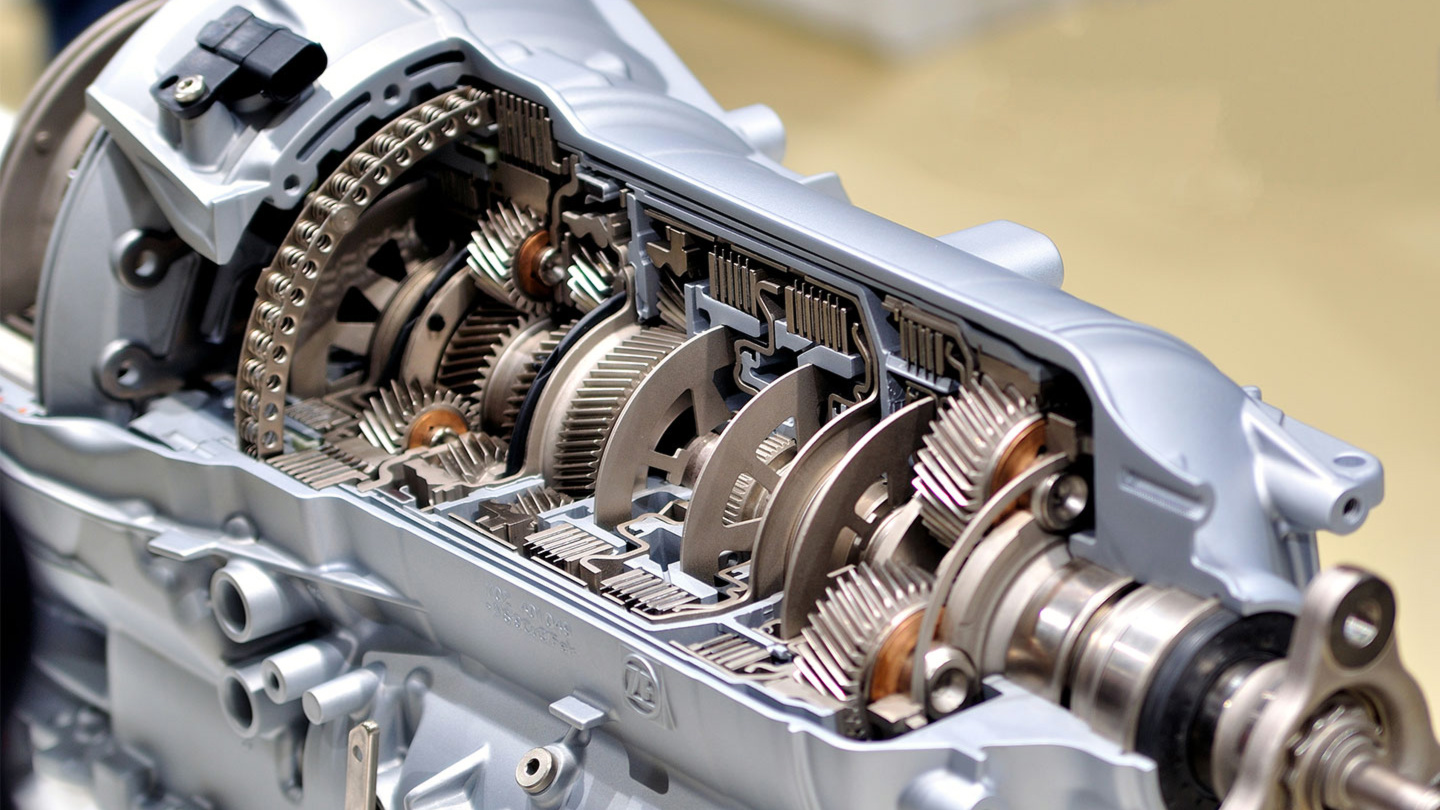

Different Components In A Gearbox

A gearbox comprises various components working together to transmit power and control motion. Key parts include:

- Gears: Toothed wheels for power and speed transfer.

- Shafts: Hold gears, and transmit rotation.

- Bearings: Reduce friction and support rotation.

- Synchronization: Smoothly engages gears.

- Clutch: Engages or disengages power for shifts.

- Planetary Gearset: Provides multiple gear ratios.

- Shift Forks: Move gears for shifting.

- Output Shaft: Connects gearbox to wheels.

- Housing: Protects, and holds components.

- Lubrication: System for reducing friction and heat.

- Seals & Gaskets: Prevent leakage and contamination.

- Mounting Points: Attach the gearbox securely.

- Transmission Control Unit (TCU): It is an electronic control module.

These elements work in tandem to control speed, torque, and direction, enabling efficient power transmission tailored to each application.

Gear Positions In A Gearbox

Gear positions in a gearbox determine speed and power.

Manual Transmission:

- Neutral: No gear engaged, engine disconnected.

- Reverse: Backward motion.

- 1st, 2nd, 3rd, 4th, 5th, 6th & so on: Varying speeds and torque.

Automatic Transmission:

- Park: Locks transmission when parked.

- Reverse: Backward motion.

- Neutral: Freely rolls.

- Drive: Automatic shifting for forward motion.

- Low: Lower gear ratios for more control.

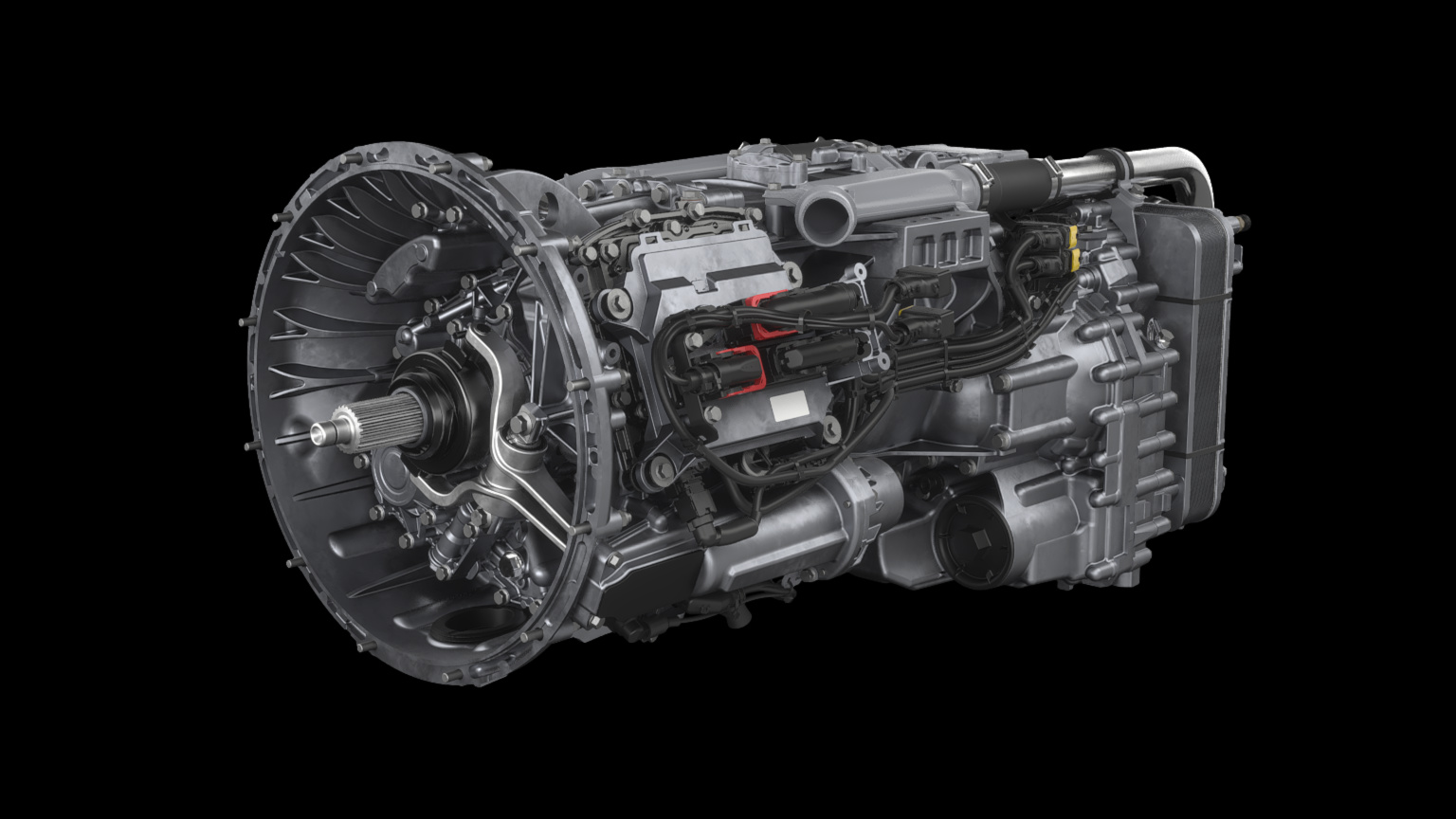

Both automatic and manual transmissions could have anywhere between 4 to 10 gears depending on the application. Heavy-duty Duty Vehicles will have up to 36 gears and sometimes more. Having more gear ratios provides even distribution of the torque and enhances the fuel efficiency.

Types Of Gearboxes

There are several types of gearboxes used in cars, each with its own design and purpose. Here are some of the main types:

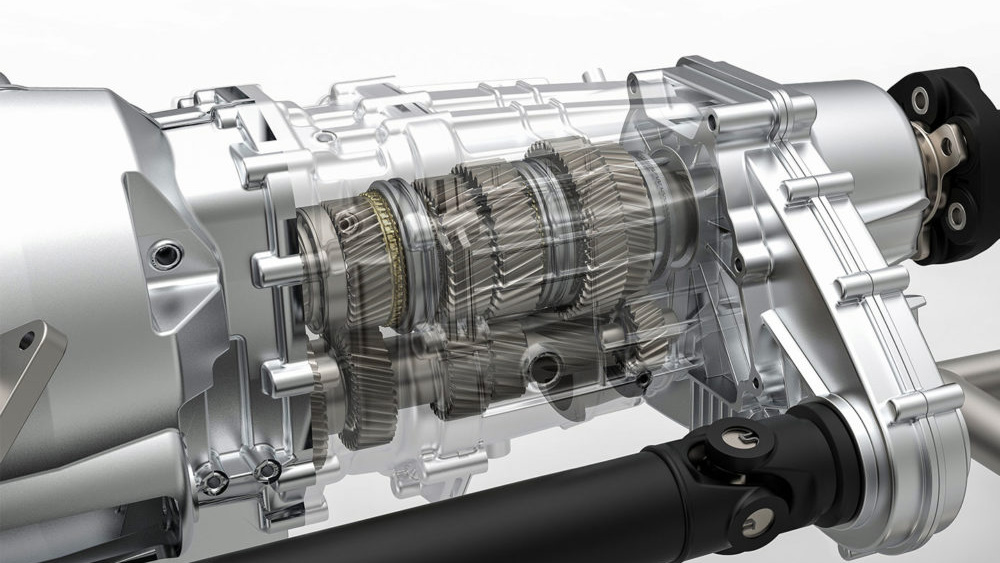

Manual Transmission (MT): Manual transmissions, also called stick-shift or standard transmissions, require the driver to manually engage and disengage gears using a clutch pedal and gear shifter. They offer direct control over gear selection and are often preferred by enthusiasts for their engagement and control.

Automatic Transmission (AT): Automatic transmissions use a torque converter or a similar mechanism to automatically shift gears without driver intervention. They are more convenient to drive in heavy traffic or on long journeys and are available in various types.

Semi-Automatic Transmission: Similar to AMTs, semi-automatic transmissions combine elements of manual and automatic transmissions. The driver can shift gears manually, or the transmission can shift automatically in certain modes.

Types Of Manual Gearboxes

Synchromesh Transmission: This is the most common type of manual transmission. It uses synchromesh gears to match the rotational speeds of the input and output shafts before engaging a gear, allowing for smoother and quieter shifts.

Non-Synchromesh Transmission: In this type, gears do not have synchromesh mechanisms. Shifting requires double clutching: first, the driver disengages the clutch, shifts into neutral, re-engages the clutch, revs the engine to match speeds, and then shifts into the desired gear.

Dog-Leg Transmission: In a dog-leg gearbox, the first gear is located to the left and backwards, while the rest of the gears follow a standard H shifting pattern. This design was historically used in racing cars to make quick upshifts easier while minimizing the chance of accidental downshifts.

Crash Box Transmission: This is an older type of manual transmission that lacks synchromesh gears, requiring double clutching and careful rev-matching for smooth shifts. It’s less common in modern vehicles.

Cable-Shifted Transmission: Some manual transmissions use cables to connect the gear shifter to the transmission, offering a different feel and mechanism compared to direct mechanical linkage.

Overdrive Transmission: Overdrive gears provide a higher gear ratio than the direct-drive gears, reducing engine RPM at cruising speeds and improving fuel efficiency.

Types Of Semi-Automatic Gearboxes

Intelligent Manual Transmission (iMT): It is a type of transmission that combines manual and automatic features. It automates the clutch operation, simplifying gear shifting for the driver. While the driver still selects gears manually, the clutch is electronically controlled, making driving in traffic less demanding compared to a traditional manual transmission.

Automated Sequential Manual Transmission: This type of semi-automatic transmission is often found in racing cars and high-performance vehicles. It allows the driver to shift gears sequentially using a lever or paddle shifters without needing to operate a clutch pedal.

Types Of Automatic Gearbox

Dual-Clutch Transmission/Direct-Shift Gearbox (DCT/DSG): DCT is a modern and performance-oriented automatic transmission. It uses two separate clutches for odd and even gear sets, enabling rapid shifts without interrupting power delivery. It offers quick and smooth gear changes, high efficiency, sporty driving experience, and often is used in high-performance vehicles. However, they are complex and expensive to manufacture and maintain.

Continuously Variable Transmission (CVT): CVT offers an infinite number of gear ratios through a system of belts and pulleys, allowing the engine to operate at optimal RPMs for efficiency and smoothness. Smooth acceleration, fuel efficiency, seamless gear changes, and adaptability to different driving conditions. It is limited in handling high torque output and can feel disconnected in sporty driving situations.

Automated Manual Transmission (AMT): AMT is a manual transmission with automated clutch and gearshift control. It uses actuators to engage and disengage the clutch and shift gears without a clutch pedal. AMTs are cost-effective, easier to drive in traffic compared to a manual, and offer better fuel efficiency than traditional automatics. However, they tend to have jerky shifts, and slower responses compared to more advanced automatics.

Intelligent Variable Transmission (iVT): iVT is an improved version of the CVT transmission. The iVT uses an advanced TCU for an adaptive performance depending on the usage of power. IVT transmission utilises a chain belt instead of the traditional push belt in the CVT. The chain system also reduces the whining sound that is observed from a CVT gearbox.

Torque Converter (TC): TC uses a fluid coupling (torque converter) to transmit engine power to the transmission. It allows for smooth gear shifts and torque multiplication. TC offers smooth and gradual power delivery and is good for heavy vehicles and towing. However, they are less efficient than other modern automatic transmissions and can have a slippage effect leading to some energy loss.

In recent times, automatic transmissions have gained popularity over manual and semi-automatic transmission. The ATs of the early years are gone. The advancements in engineering have allowed automatic transmissions to become better than manual transmissions in almost every possible way.

Check out our list of used cars for sale in the UAE and new cars for sale in the UAE.